Block sanding techniques are crucial for achieving flawless finishes in auto body repair. This process involves using power sanders with block attachments and abrasive paper to correct surface imperfections, from minor paint issues to intensive metal prep. The key lies in choosing the right tools (adjustable sanders, grits) tailored to each task, maintaining consistent pressure & coverage, cleaning tools regularly, and ensuring proper ventilation. Master these techniques for top-quality auto body services.

In auto body shops, achieving smooth finishes requires a precise understanding of block sanding techniques. This comprehensive guide delves into the art and science behind this essential process, providing a step-by-step approach for optimal results. From selecting the right tools and materials to mastering best practices, learn how effective block sanding can transform rough surfaces into flawless, ready-for-paint finishes. Discover expert tips to ensure consistency, quality, and efficiency in your auto body shop.

- Understanding Block Sanding: Tools and Materials

- Step-by-Step Guide to Effective Block Sanding Techniques

- Best Practices for Achieving Smooth Finishes in Auto Body Shops

Understanding Block Sanding: Tools and Materials

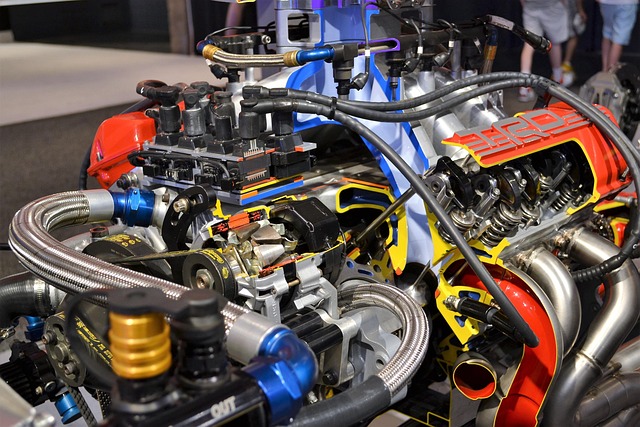

Block sanding is a crucial technique in auto body shops for achieving smooth, flawless surfaces during fender repair or dent repair processes. This method involves using a power sander with a block attachment to apply abrasive paper strategically over car panels. The process is versatile and effective for various surface corrections, from removing paint imperfections to preparing metal for painting, making it an indispensable tool in the automotive industry.

The right tools and materials are essential for successful block sanding. Auto body shops require power sanders with adjustable settings for different grits of abrasive paper. A variety of block shapes and sizes is also necessary to reach tight spots and contoured surfaces. For optimal results, professionals choose fine-grit papers for delicate work and coarser ones for heavier sanding tasks in car collision repair scenarios.

Step-by-Step Guide to Effective Block Sanding Techniques

Block sanding is a crucial step in the auto body repair process, ensuring smooth surfaces and precise finishes. Here’s a straightforward guide for achieving expert results:

1. Prepare Your Workspace: Ensure adequate ventilation, don safety gear including gloves, goggles, and a respirator mask, and lay down drop cloths to protect the surrounding area from debris.

2. Choose the Right Sanding Block: Select blocks suitable for your project’s specific needs. Different grits (from coarse to fine) are designed for distinct stages of auto body repairs, with higher grit numbers indicating smoother finishes.

3. Apply Compound and Start Sanding: Generously apply blocking compound onto the damaged area, following the product’s instructions for optimal results. Securely hold the sanding block at a slight angle and apply even pressure as you move it in straight lines or circular motions across the compound, eliminating imperfections layer by layer.

4. Work Methodically: Move from coarser grits to finer ones, consistently checking the surface for smoothness after each pass. This systematic approach ensures a seamless transition between sanding stages.

5. Inspect and Repeat: Regularly inspect your work under good lighting conditions. If necessary, repeat the process, working in thin layers until you achieve the desired finish, smooth as needed for top-quality auto body services.

Best Practices for Achieving Smooth Finishes in Auto Body Shops

Achieving smooth finishes in auto body shops involves a meticulous process that starts with understanding and mastering block sanding techniques. The key lies in using the right grits of sandpaper, typically starting with coarser grains for aggressive removal of imperfections and gradually transitioning to finer grains for smoothening. This multi-step approach ensures that each layer is perfectly aligned with the previous one, creating a seamless surface ready for painting.

Best practices include maintaining consistent pressure while sanding, ensuring even coverage across the panel. Using a block sander with adjustable speed settings allows for precise control over the sanding process, enabling efficient removal of paint and imperfections without damaging the car’s surface. Regular cleaning of the sandpaper and sander between applications prevents debris buildup, which can cause scratching or uneven results. Additionally, proper ventilation in the work area is crucial to prevent the inhalation of harmful dust particles during the sanding process, especially when dealing with car scratch repair or automotive repair tasks.

Block sanding techniques are essential for achieving smooth finishes in auto body shops. By understanding the right tools, materials, and step-by-step processes, professionals can efficiently refine surfaces, preparing them for high-quality paint jobs. Adhering to best practices ensures consistent results, minimizing imperfections and promoting a flawless final product. Mastering these techniques is a game-changer for any auto body shop seeking to deliver top-notch repairs.