Block sanding techniques are essential for auto bodywork professionals, offering a precise method to achieve smooth surfaces crucial for finishes like painting. Effective labor scheduling, by strategically planning and assigning tasks, optimizes shop operations, reduces downtime, and ensures prompt project completion while maintaining quality standards. Combining these techniques dramatically improves vehicle bodywork outcomes in car dent repair services.

In the realm of woodworking, achieving smooth finishes demands a meticulous approach—one that integrates advanced tools and precise planning. This article explores the art of block sanding techniques, providing a comprehensive guide to mastering this crucial step in crafting superior surfaces. From understanding the various sandpaper types to implementing efficient labor scheduling coordination, we delve into strategies that ensure seamless projects. Uncover best practices for integrating sanding and scheduling, ensuring your workshops run smoothly and produce exceptional results.

- Understanding Block Sanding Techniques: A Comprehensive Guide

- Efficient Labor Scheduling Coordination for Smooth Projects

- Integrating Sanding and Scheduling: Best Practices for Success

Understanding Block Sanding Techniques: A Comprehensive Guide

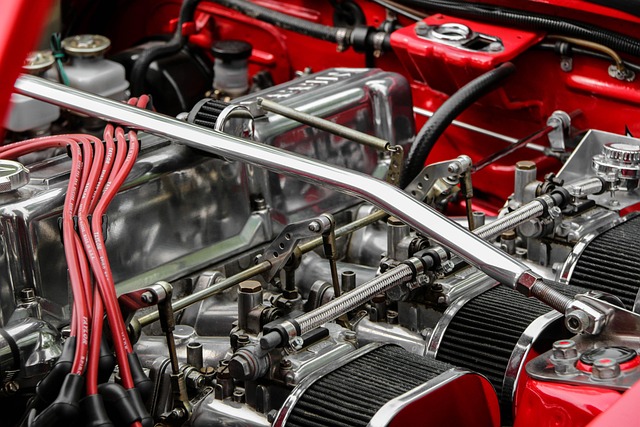

Block sanding techniques are a fundamental aspect of auto bodywork and collision center operations. This method involves using sandpaper blocks of various grits to even out surfaces, remove imperfections, and prepare the auto body for painting or other finishing processes. A comprehensive guide to block sanding educates professionals at auto body shops on selecting the right tools, understanding different grits, and mastering application techniques to ensure consistent quality.

By employing these techniques effectively, technicians can achieve seamless finishes in their work. This involves carefully planning the sequence of sanding steps, starting with coarser grits for heavy removal and progressing to finer grits for a smooth surface. The right scheduling coordination—including labor allocation and project management—is crucial to ensure that block sanding is performed efficiently within the collision center’s operations, leading to higher customer satisfaction and faster turnaround times at the auto body shop.

Efficient Labor Scheduling Coordination for Smooth Projects

Efficient Labor scheduling coordination is pivotal for successful projects in any auto body shop offering block sanding techniques. By meticulously planning and allocating resources, workshops can streamline operations, reduce downtime, and ensure timely project completion. This involves factoring in specialized tasks like block sanding, which requires skilled technicians and specific equipment. Effective coordination means having the right person for each job, minimizing wait times, and maximizing productivity.

In automotive collision repair or car body repair, seamless labor scheduling is a game-changer. It prevents delays that could arise from overloading a single technician or misaligning tasks. With proper planning, auto body work benefits from a structured workflow, enabling technicians to focus on intricate block sanding techniques without unnecessary interruptions. This coordination ensures customer satisfaction by delivering vehicles promptly and with the highest quality standards met.

Integrating Sanding and Scheduling: Best Practices for Success

In the realm of automotive aesthetics, combining effective block sanding techniques with meticulous labor scheduling is a powerful duo that ensures top-notch vehicle bodywork results. Block sanding, a precision method for achieving smooth surfaces, is integral to preparing car dent repair and other body shop services. By strategically integrating this technique into the workflow, body shops can enhance productivity while maintaining quality standards.

To achieve success, consider allocating dedicated time slots for block sanding within the overall labor schedule. This ensures that skilled technicians are available to execute these delicate tasks without disruptions. Additionally, utilizing advanced tools designed for block sanding can expedite the process, allowing for a more streamlined and efficient repair pipeline. In the fast-paced world of car dent repair, this coordination is vital to meeting customer expectations and delivering exceptional body shop services.

In conclusion, mastering block sanding techniques and implementing efficient labor scheduling coordination are key to achieving seamless project completion. By understanding the nuances of block sanding, from its comprehensive guide to best practices, and synchronizing labor schedules with meticulous planning, professionals can enhance productivity and deliver exceptional results. These integrated strategies form the backbone of successful projects, ensuring smooth operations and high-quality outcomes.